High pressure pump was large and expensive in old time, but nowadays, the structure of high pressure axial piston pump is very simple, while the development has generally gone through two stages: oil lubrication and pure water lubrication, the latter one will be more efficient and economical.

Because the lubrication of oil is much better than pure water, before the new material and its processing means have not been fully mature, in the pure water hydraulic pump, pure water only as a pressure carrier of energy and control signals, its bearing parts are lubricated by oil isolated from high pressure pure water with seals, at this time, the pump is generally valve distribution axial piston type, between the pistonand the swash plate for point contact or line contact, Its advantages are that the structure of the pump is very simple, stable performance, good reliability, low cost; Disadvantages are large volume, heavy weight, only suitable for the occasion of low output pressure, generally less than 10MPa, because in the state of high pressure, seals wear faster, the sealing effect decreases, often easy to cause oil and water collusion, and the piston head wear is also faster.

With the advancement of material science and processing technology, the performance of ceramic and polymer materials has been greatly improved, processing and handling are easier, and the cost of components has decreased. At this time, the pure water hydraulic pump uses pure water to lubricate all its bearing parts, and most of them are end face distribution axial piston type, and the surface contact between the piston and the swash plate is hydrostatic lubrication or mixed lubrication. At this time, the pump has compact structure, small size, light weight, high output pressure, pump rated pressure can reach 16MPa, and good performance and reliability.

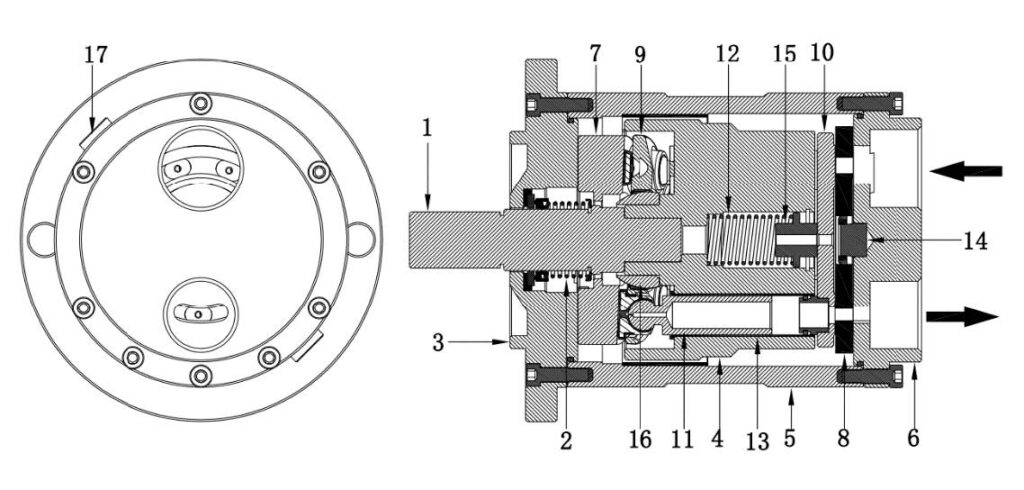

The following is the structure of axial piston pump

| Part No. | Name | Part No. | Name |

| 1 | Main Shaft | 11 | Piston |

| 2 | Shaft Seal | 12 | Spring |

| 3 | Mounting Flange | 13 | Bushing |

| 4 | Cylinder Barrel | 14 | Guide Pin |

| 5 | Casing | 15 | Top Pin |

| 6 | Port Flange | 16 | Piston Shoes |

| 7 | Swash Plate | 17 | Plug |

| 8 | Port Plate | ||

| 9 | Retainer plate | ||

| 10 | Valve Plate |