The most used equipment on board is marine pumps, centrifugal pumps, positive displacement pumps and eductors, and marine centrifugal pumps are the most widely used among them, but what is the structure of marine centrifugal pumps?

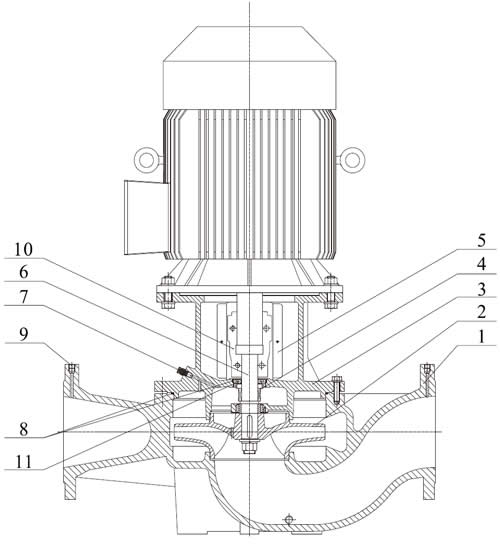

| Part No. | Name | Material |

| 1 | Casing | HT200/QT450/ZCuZn16Si4 |

| 2 | Impeller | ZCuZn16Si4/ZCuSn5Pb5Zn5 |

| 3 | Casing Cover | HT200/QT450/ZCuZn16Si4 |

| 4 | Mechanical Seal | TC-CA/ TC-TC |

| 5 | Coupling Guard | 1Cr18Ni9 |

| 6 | Pump Shaft | 1Cr18Ni9 |

| 7 | Air release bolt | 1Cr18Ni9/ZCuZn16Si4 |

| 8 | Seal O Ring | EPDM |

| 9 | Plug | 1Cr18Ni9/ZCuZn16Si4 |

| 10 | Coupling | QT450 |

| 11 | Seal Cover | 1Cr18Ni9 |

1. Pump casing and pump cover. It is the main fixed part of the centrifugal pump. It consists of a pump casing and a pump cover with an inner cavity made into the shape of an escargot, both of which are made of cast iron or bronze. The latter can be used for marine seawater pumps and is corrosion-resistant. A stuffing box is provided at the contact between the center of the casing and the pump shaft, and positioning pins are provided on the joint surface of the pump cover and the pump body for easy disassembly, installation and positioning.

2. Impeller. It is the main moving part of the centrifugal pump. It is made of several blades and the front and rear side plates. It is installed on the pump shaft and connected by keys. The material is usually stainless steel or bronze. Commonly used impellers’ types are integral, semi-open and fully open.

3. Seal ring. Also called water blocking ring or watertight ring. It is a O ring installed between the water inlet of the centrifugal pump impeller and the pump cover. Its main function is to prevent the water in the discharge chamber (high pressure) from returning to the suction chamber (low pressure), causing serious internal leakage. Commonly used materials is bronze.

4. Mechanical seal. The shaft seal device of marine centrifugal pump generally adopts mechanical seal. The mechanical seal structure is that the static ring installed in the casing of the sealing device is fixed on the pump casing through the positioning pin. And it protects the sealing contact between the end faces of the moving ring installed on the shaft to seal the fluid. When the ring is worn, the spring pushes the thrust rod to keep the moving ring and the static ring in good contact. Compared with the stuffing box type sealing device, the mechanical seal has the characteristics of less wear, long service life and good sealing effect, but the structure is complicated, the installation precision is high and the price is expensive.